Description

Dual Cylinder Hydraulic Ironworker 60T-160T

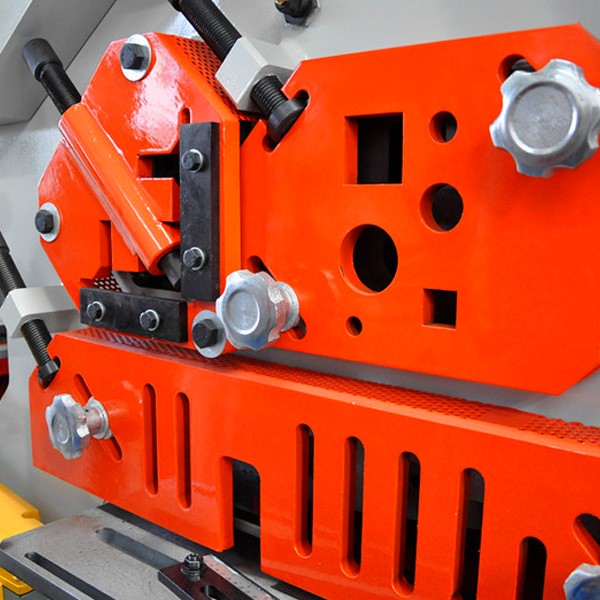

Looking to increase productivity in your shop? This hydraulic ironworker enables 2 operators to work independently at any of the machine’s

5 stations. Plus, the machine’s pure vertical movement minimizes distortion and delivers clean cuts every time.

Runs on 220/380/415/600-volt 3-phase power.

60-160 tons of punching pressure force.

5 integrated workstations each execute a different function: punching, notching, flat bar shearing, angle shearing, and bar shearing.

Dual-operator design enables 2 people to work at opposite ends of the machine simultaneously without loss of power at either station.

Hydraulic cylinders use entirely vertical movement to perform all functions.

Electric backgauge and adjustable material stops save you effort and deliver precise results for production runs.

Large worktables separate into 2 pieces, allowing you to get angle iron and oddly-shaped materials to the punch without difficulty.

Different size and shape of punches and dies to accommodate a variety of applications.

Foot pedal provides convenient stop and start control.

Adjustable stroke control of both the upward and downward strokes limits movement and reduces costs.

Deep throat depth at the punch station handles large pieces of material and increases capacity.

Hydraulic hold-downs at the shear station ensure safe operation and even cuts.

Waste buckets keep your shop neat and reduce time spent on clean-up.

Heavy structural steel plate framework ensures rigidity and eliminates flexing.

KINGSTON covers this ironworker with 13 months parts warranty and lifetime technical support.

|

Model |

KIW-60/D |

KIW-90/S/D |

KIW-120/S/D |

KIW-160/S/D |

||

|

Hole Punching |

Punching Pressure (KN) |

600 |

900 |

1200 |

1600 |

|

|

Max. Punching Capacity (D* T) (mm) |

Φ25*16 |

Φ30*20 |

Φ35*25 |

Φ38*30 |

||

|

Depth of Throat(mm) |

300 |

355 |

400 |

600 |

||

|

Ram Stroke(mm) |

80 |

80 |

80 |

80 |

||

|

Number of Stroke (times/min) |

8-22 |

8-22 |

8-22 |

8-22 |

||

|

Flat-bar Shearing |

Angle of Shear |

7° |

8° |

8° |

8° |

|

|

Max. Shearing Thickness(mm) |

16 |

20 |

25 |

30 |

||

|

Flat Bar (T×W)(mm) |

16×250 |

20×330 |

25×330 |

30×355 |

||

|

8×400 |

10×480 |

16×600 |

20×600 |

|||

|

Angle Steel Shearing |

90° shearing (mm) |

120×10 |

140×12 |

160×14 |

180×16 |

|

|

45° shearing (mm) |

70x8 |

70x10 |

80x7 |

80x10 |

||

|

Profile Steel Shearing |

Round Bar (mm) |

45 |

50 |

60 |

65 |

|

|

Square Bar(mm) |

40 |

45 |

50 |

55 |

||

|

T-bar(mm) |

120x12 |

140x12 |

160x14 |

180x16 |

||

|

I-beam (mm) |

126 |

160 |

200 |

280 |

||

|

C-channel (mm) |

126 |

160 |

200 |

280 |

||

|

Notching |

Thickness(mm) |

10 |

10 |

10 |

10 |

|

|

Width(mm) |

80 |

80 |

90 |

90 |

||

|

Depth(mm) |

100 |

100 |

100 |

100 |

||

|

Material Tensile Strength (N/mm2) |

450 |

450 |

450 |

450 |

||

|

Motor Power (KW) |

4 |

5.5 |

7.5 |

11 |

||

|

Overall Dimension (L×W×H ) |

Length(mm) |

1650 |

1950 |

2350 |

2680 |

|

|

Width(mm) |

800 |

900 |

980 |

1060 |

||

|

Height(mm) |

1780 |

1930 |

2100 |

2380 |

||

|

Gross Weight(Kg) |

1800 |

2600 |

4800 |

6800 |

||